Insulating project ROI – Why proven insulation solutions matter now more than ever

Fig 1:

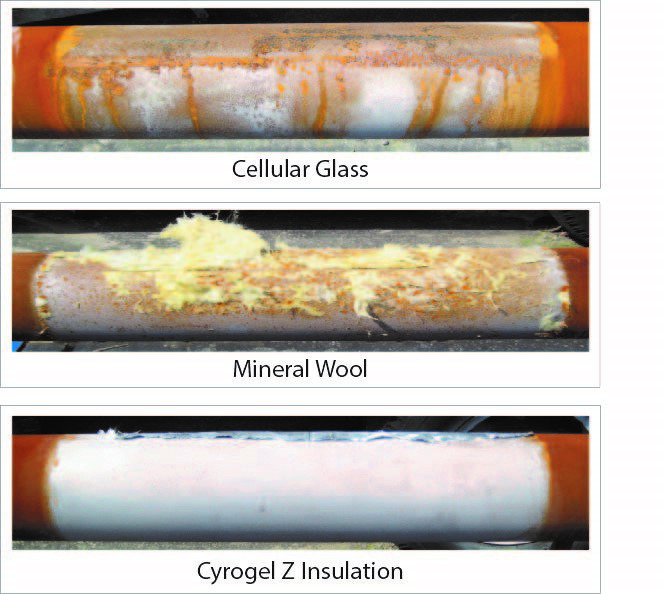

The type of insulation specified can have significant impact on long term expenses associated with CUI and CUF. The above images show how quickly corrosion can begin to occur under traditional cellular glass and fibrous insulation materials.

All three pipes were insulated and exposed to the elements for 90 days during a typical northeast summer. The bottom image shows the superior resistance of Cryogel to corrosion under insulation.

Fig 2:

A 300’ long section of pipe, fully insulated with Aspen Aerogels blanket, being hoisted into a module rack. The flexible design enabled off-site construction of large modules, condensing the overall build schedule, simplifying module connectivity, minimizing insulation rework, and enabling start up in record time.

As the world faces an increasing global demand for energy, the need for industrial projects to be built faster, produce more, reduce energy consumption, be safer, and drive profitability is more critical than ever.

Whether your industry is oil, gas, or petrochemical, or your processes run hot or cold, insulation is a critical facility component in achieving the above needs. Investing in the right insulation early in a project has been shown to help deliver project quality, without sacrificing overall project time or budget. Achieving the balance of these classic three constraints is how a project leader will measure success and realize the desired return on investment (ROI). Whether your project responsibility is ownership, project design, site construction, or maintenance, understanding the impact of insulation can be critical to the project success. Aspen Aerogels® has been proving the ROI value of high-performance industrial insulation for decades.

Unfortunately, insulation is often thought of as a necessary cost rather than being considered for the myriad of benefits it can provide. What many fail to recognize is how insulation can play a critical role in ensuring project ROI.

So how can insulation drive ROI? When evaluating the ROI of a project insulation system, consider value beyond only thermal benefits. Can the insulation system help:

- Simplify design

- De-risk the construction schedule

- Increase potential revenue

- Minimize downtime

- Reduce unplanned maintenance

- Improve safety and environmental impact

Keeping it Hot

Throughout refineries and petrochemical facilities, maintaining hot processes is critical to delivering product quality and quantity. Especially challenging are cyclical processes, where temperature control and corrosion under insulation (CUI) mitigation are most difficult. Aspen Aerogel’s family of Pyrogel® insulation products keep these processes running as designed. Pyrogel insulation has been installed in thousands of applications and is known as an industry leader in protecting systems from CUI, minimizing maintenance and unplanned shutdowns.

In refineries, few materials can withstand the severe requirements for use in delayed coker units or cracking units. Installation of Pyrogel insulation has enabled multiple ethylene recovery unit projects to improve product yield, resulting in >$500,000 increased revenue/year. In yet another facility, installation of Pyrogel insulation as part of a CUI mitigation strategy, resulted in $8M in downtime recovery.

When the cost of insulation is often less the 5% of an overall project budget, yet insulation can have a dramatic impact on the outcome, the ROI for Pyrogel insulation is easy math. Pyrogel insulation can help:

- Reduce space and weight constraints

- Mitigate CUI

- Enable fast installation with fewer/no callbacks

- Increase yields

- Shorten maintenance schedules

- Reduce shutdowns

Keeping it Cool

The return on investment for cold applications might be even easier to calculate, which is why Cryogel® insulation is used in LNG facilities and cold process protection in even the hottest, humid environments.

Cryogel insulation has been the preferred cold insulation solution when construction schedules are tight and long-term performance is critical. The durable, yet flexible, design allows for offsite construction and transport. No contraction joints equate to faster construction and less potential for water vapor leaks. Intuitive installation reduces callbacks and enables fast training of new contractors. Multiple layers of vapor barrier provide excellent long-term vapor intrusion control. The blanket design simplifies construction and logistics, enabling one material solutions to be used in a multitude of facility applications, saving space and time. Add the inherent acoustic and passive fire protection capabilities, and the result is an insulation system that provides more than just thermal protection.

In a recent North American project, Cryogel insulation outperformed the incumbent insulation in terms of fewer installation issues and overall time to construct. Because of the time savings, the contractor was able to reverse a 2-month delay in the construction schedule. In another case, a knowledgeable EPC specified Cryogel insulation upfront, and the benefits of specification from design through construction enabled months of schedule reduction versus experience utilizing traditional insulation. Not to go unmentioned, Cryogel insulation is also now installed on the longest LNG jetty in the world.

In addition to superior thermal performance, Cryogel insulation improves ROI through:

- Fewer failures – no contraction joints, multiple layers of vapor barrier protection

- Increased yields – reduce BOG, less downtime for inspection/repair

- Improved facility safety – providing passive fire protection

- Better environmental impact – improved energy efficiency, operational noise reduction

Performance. Proven.

If you are an engineer designing a new or expanded facility, a contractor responsible for material selection and installation, or a facility manager relied upon for delivering operational excellence, managing project risk, and delivering project ROI is critical to success. Aspen Aerogels is the only aerogel solution that can prove the ability to withstand the test of time, with materials installed in the harshest environments and most challenging processes, protecting people and assets for decades.

Learn more about how Aspen Aerogel’s family of high performing insulation materials provides both short term and long-term value to your project.