Supporting BEV Performance

& Safety Targets for OEMs Globally

We look forward to engaging with your team in person

20+ Years Manufacturing High-Performance Aerogel Solutions at Scale

Founded in 2001 to harness the remarkable properties of nanometer-scale materials, Aspen Aerogels has designed, engineered, and commercialized a robust portfolio of game-changing thermal and fire protection solutions. Aspen has also developed and continues to refine aerogels for various battery materials, including anode, cathode, and solid-state cell applications for ternary and LFP chemistries.

Evolving from Material Manufacturer to Tier 1 Supplier

Early Automotive Engagements

- Early 2000s: Improving process energy efficiency at automotive assembly plants

- 2010s: Passenger comfort and thermal management solutions for ICE vehicles

- 2016: Tier 3 supplier for Chinese EV manufacturers (including BYD), who adopted our Energy Industrial products to address thermal management challenges

Delay or Stop Thermal Runaway

- In 2019, we applied knowledge gained from applications of our aerogel materials in battery packs by Chinese customers to rapidly develop and deploy next-generation thermal protection, PyroThin® thermal barriers

- PyroThin thermal barriers evolved from almost 20 years of material and engineering solutions development

- OEMs worldwide recognized the ability of PyroThin cell barriers to help them achieve goals of thermal propagation delay and stop in line with ECE100, GB38031, and UN GTR 20 regulations

As of Q3 2024, Aspen is a Tier 1 & 2 Supplier to GM, Toyota, Stellantis, Scania, Audi, and Porsche

Engineering Agility & Responsiveness

PyroThin aerogel materials and thermal barriers are manufactured in-house at scale. Combining our production capabilities with our class-leading engineering team enables Aspen to support the rapidly changing evolution of OEMs’ module or pack designs, primarily driven by the maturity of cell manufacturing up to and beyond nomination and SOP.

Innovation and Technology Leadership

Aspen has led the industry in research, development and commercialization of our proprietary Aerogel Technology Platform® for more than 20 years. Our technology is protected by patents and patents pending worldwide that have been consistently validated in the courts in Europe, Asia and the United States.

Beyond Thermal Barriers

While Aspen is recognized as a pioneer in thermal and fire protection based on our silica aerogels, we are also developing battery materials utilizing our carbon aerogel technology. We have invested in a specialized battery materials capable of producing pilot-scale pouch cells.

This group is funded by a blend of in-house and government grants; most recently, we secured a $7M US Government award to further develop our LFP cathode solutions. Cells leveraging this LFP technology are expected to fully charge within 5 to 10 minutes.

What is Aerogel?

Aerogel is a classification for highly porous solids where the porosity is measured in nanometers. Aspen Aerogels functionalizes this porosity to sustain the required performance, whether as a thermal insulator, a nano-spring in the case of PyroThin cell barriers, or a highly accessible conductive ion pathway for anode and cathode applications. Aspen has pioneered aerogel design and process scaling to produce sustained performance, critical to the lifecycle delivery of safety solutions.

Award-Winning Thermal Runaway Solutions & Engineering Partnerships

- Automotive News PACE Award: The PACE program celebrates suppliers that demonstrate exceptional ingenuity and technological advancement, helping set a standard for industry best practices.

- Automotive News PACE Innovation Partnership: General Motors and Aspen collaborated closely to develop a thermal runaway propagation solution with PyroThin, which is in high-volume serial production with passenger and commercial vehicle OEMs.

- GM Supplier of the Year, Overdrive Award for Launch Excellence: PyroThin’s proprietary technology and Aspen’s agile engineering support played a crucial role in GM’s thermal runaway propagation strategy for its Ultium battery platform.

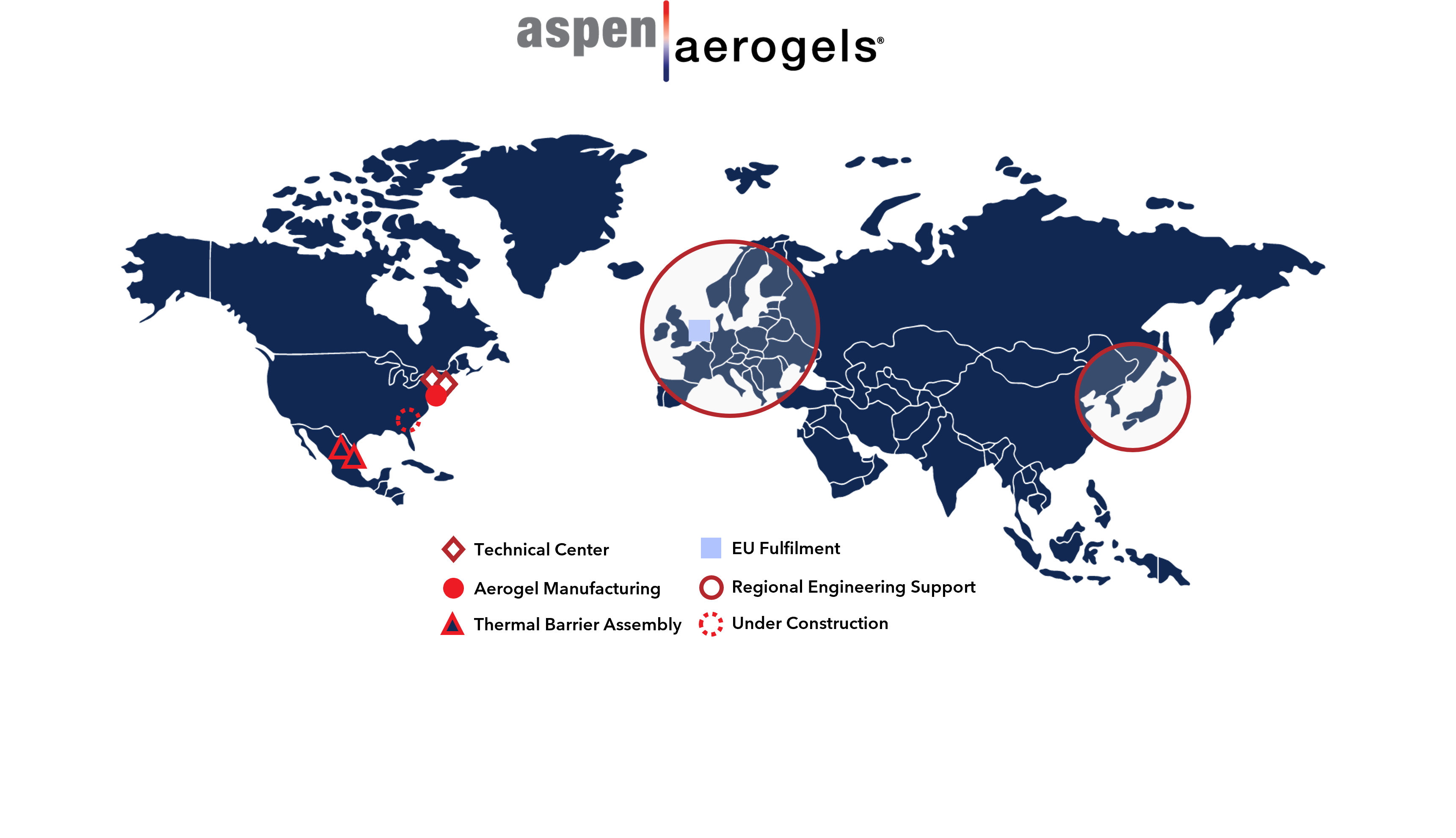

We Support BEV Programs Globally

We have a robust network of multilingual engineers and commercial staff based in Europe, Asia, and North America.

Invest in a Partner That Will Grow With You

Please submit your questions for our upcoming in-person discussion

Christopher Schneider

Battery Thermal Business Development Leader

+49 (0) 172 770 9600